The

Search for unmachined parts detects fitting unmachined parts for the production of

finished parts or finished parts which can be produced from a certain

unmachined part.

Search for unmachined parts detects fitting unmachined parts for the production of

finished parts or finished parts which can be produced from a certain

unmachined part.

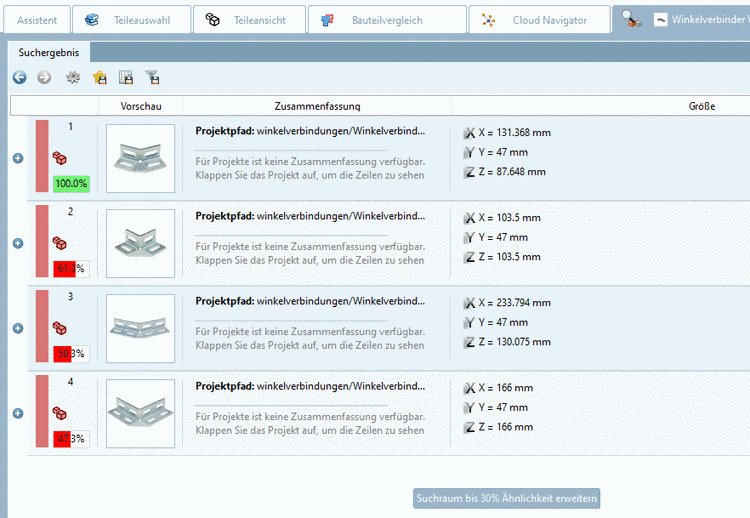

The search detects, whether a part is completely contained in another part: The finished part has to be smaller than the unmachined part, so that it can be produced by removing wasted material. As soon as the extensions of the finished part exceed the ones of the unmachined part only at a certain point, it cannot be used at all or at least badly.

The search calculates the volume of the material to remove (waste). The less material to remove, the higher the ranking in the result list, because this criterion is determining for the manufacturing costs.

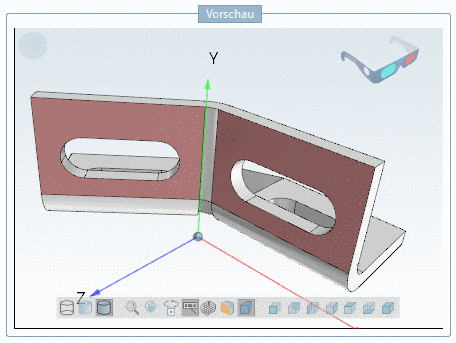

In the Part comparison you can compare the finished part with found unmachined parts.

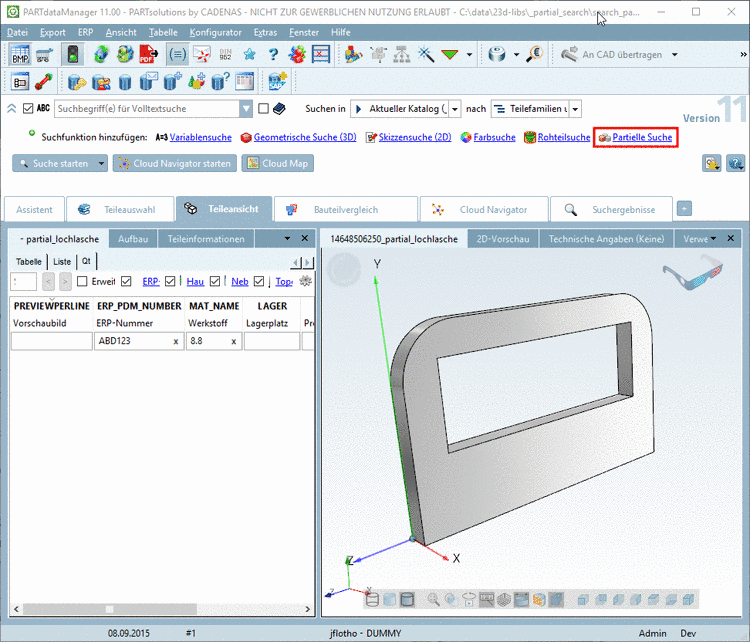

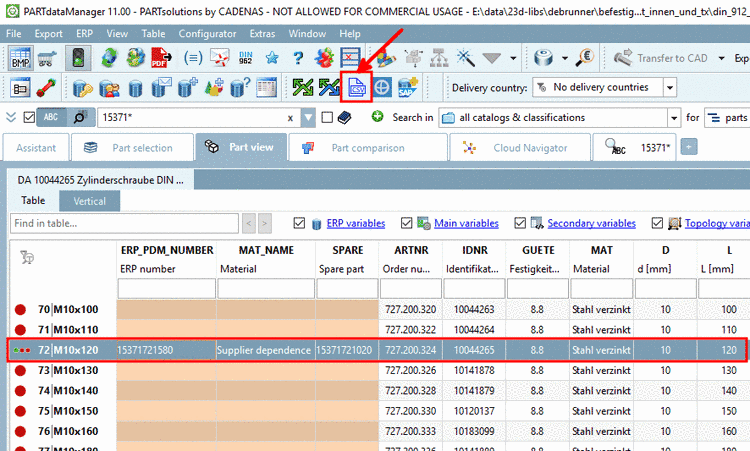

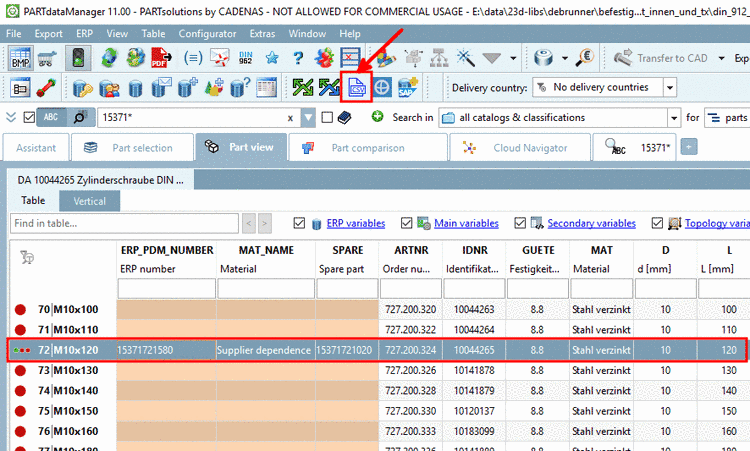

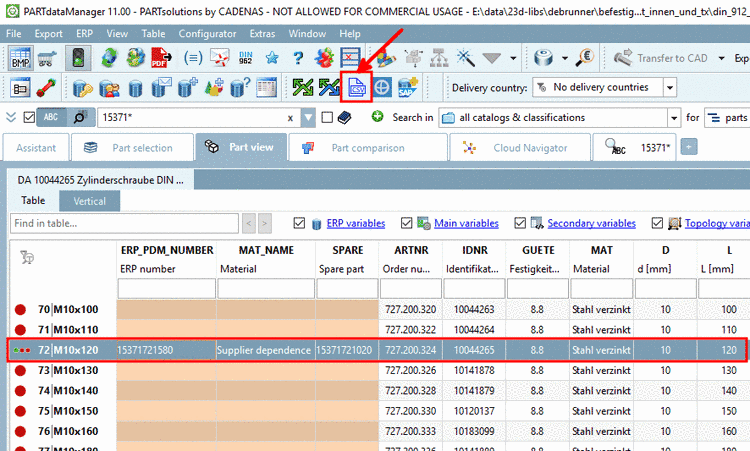

Click on

Search for unmachined parts.[61]

Search for unmachined parts.[61]

-> The same-named dialog box is opened.

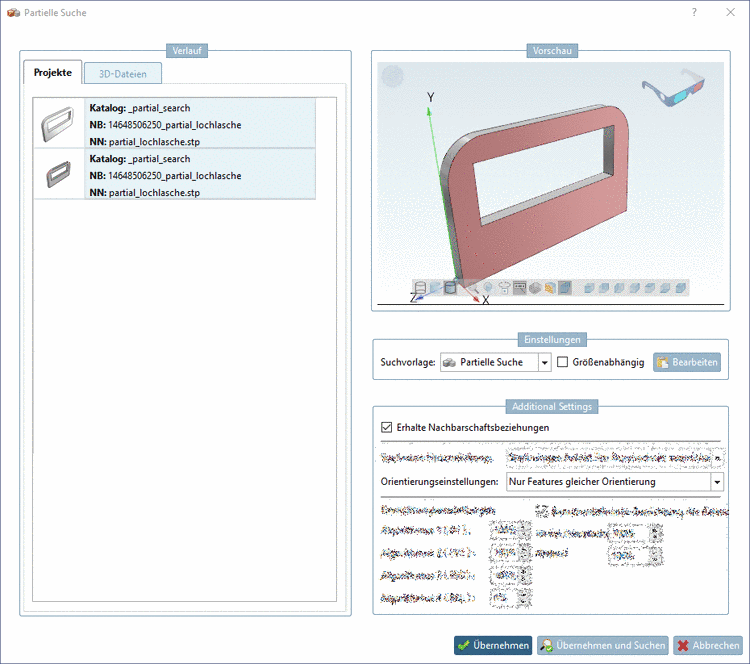

On the left side, under History, select the desired search part.

Accepted error in finished part

The error is caused by missing material at the unmachined part.

Maximum waste in unmachined part

The maximum waste defines how much material may be removed from the unmachined part.

Resolution: (16 | 32 | 64 | 128)

The resolution controls the search quality. When choosing a higher resolution more details are gathered, however, the search lasts a little bit longer.

Closes the dialog box and starts Search for unmachined parts immediately.

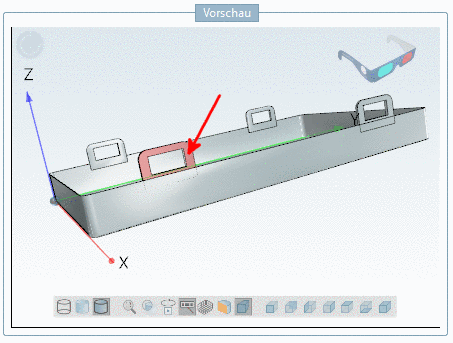

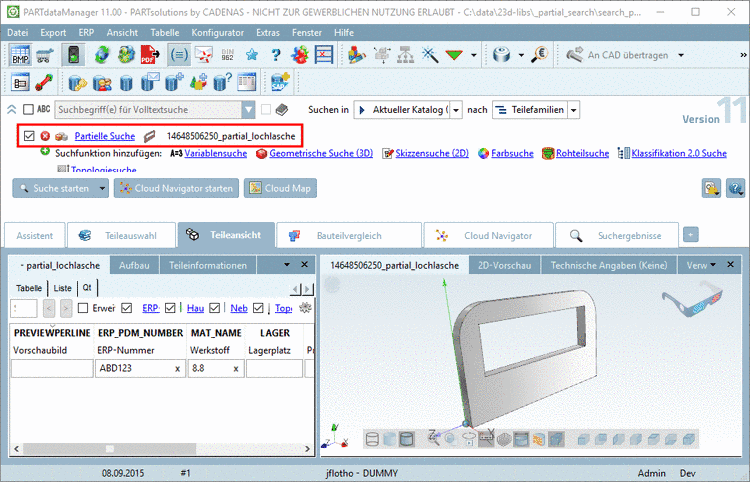

-> Search for unmachined parts is displayed with a small preview image now.

Under Search in determine the directory to be searched. Under "for" select the option parts.

Click on .[62]

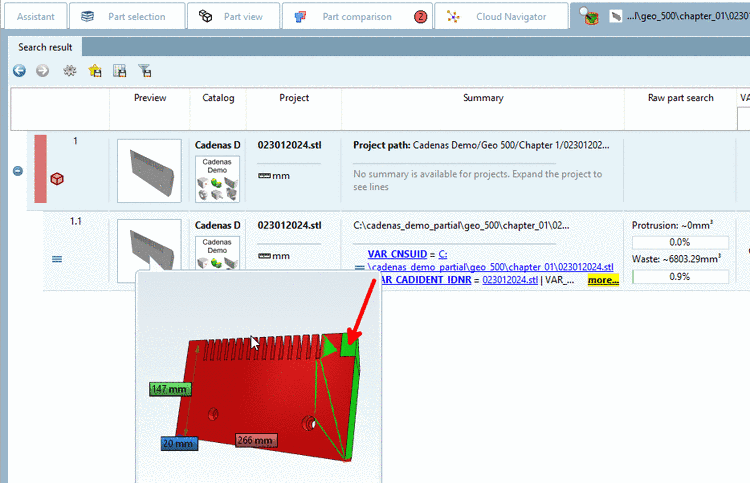

-> The search results are listed. The column Search for unmachined parts shows Protrusion and Waste. In the tooltip, the waste is colored.

Optionally, you can load search and compare part into the Part comparison. When moving the mouse over a result line different buttons are displayed.

Click on the button Compare to search-part.

In the part comparison, different compare functions are available. Details on the part comparison can be found under Section 3.1.6.10, “ Part comparison ”.

[61] When

searching with one single part call the  Search for unmachined parts from the standard search methods area. The

advantage is that it can be combined with other methods such as

Full-text search (additional

information like material), Variables search or Topology search).

Search for unmachined parts from the standard search methods area. The

advantage is that it can be combined with other methods such as

Full-text search (additional

information like material), Variables search or Topology search).

When searching with multiple search parts further on use the "Search for unmachined parts" via Purchineering functionality. On this see Section 3.1.13.3, “ Unmachined / Finished part report ”.

[62] The combination with Geometric search (3D), Sketch search (2D) and Color Search is not possible.