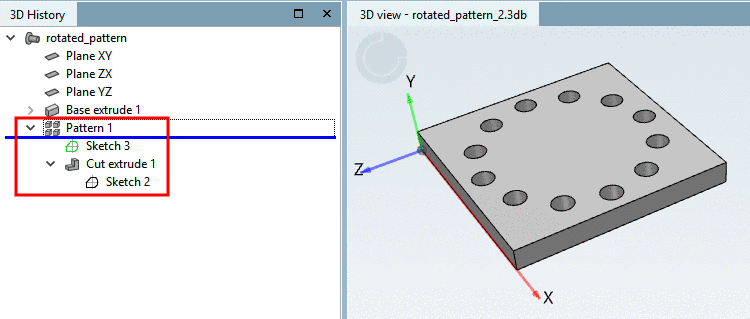

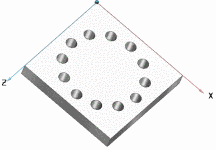

In rotated patterns the borings are circularly arranged around a central point.

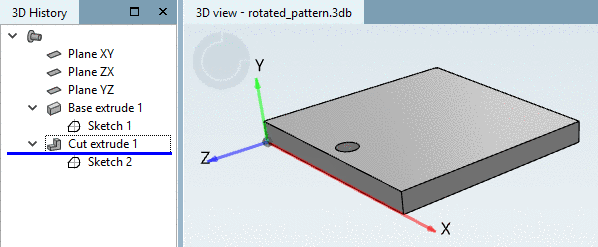

The following example shows the design process of a rotated pattern step by step in detail.

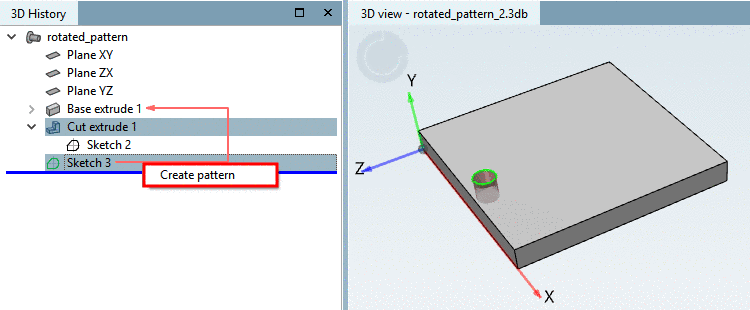

Initial situation: The origin boring is already created by Cut extrude (Sketch 2). It shall be copied in circular form so that 12 borings are created in total.

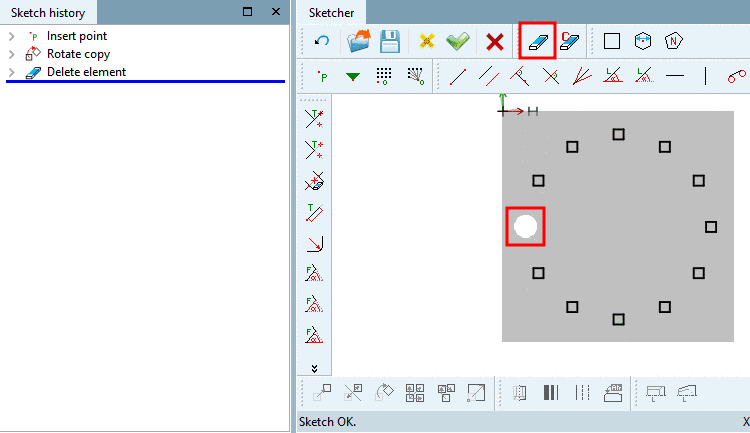

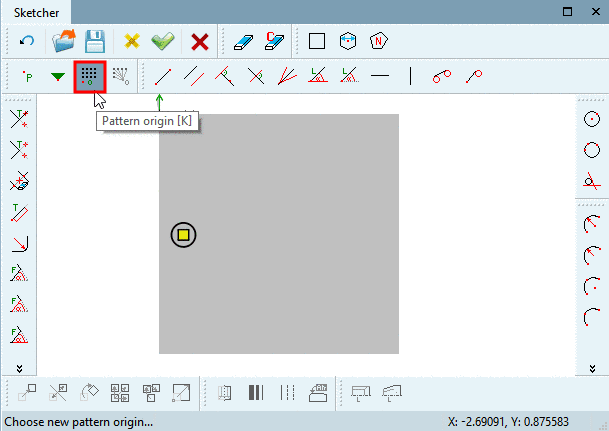

Open the sketch containing the origin boring and set the pattern origin on the boring via button Pattern origin.

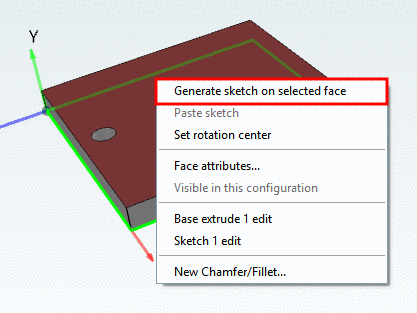

Via Generate sketch on selected face, create a new sketch for the pattern.

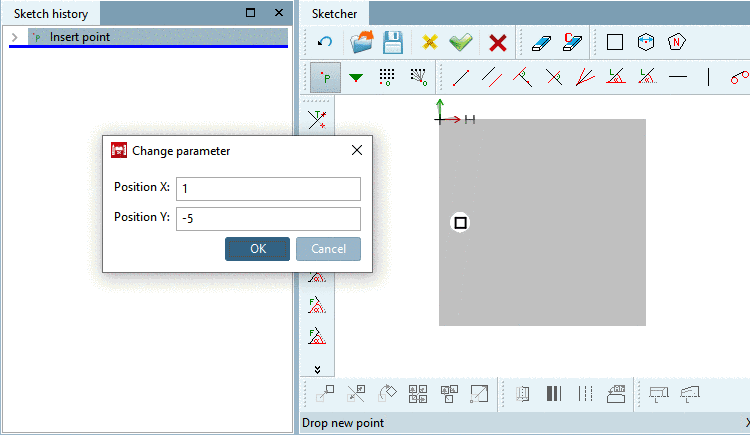

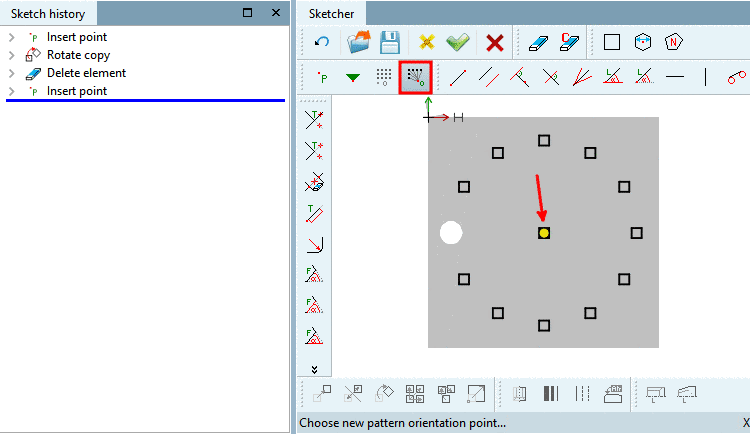

In this sketch, set the starting point for the pattern design exactly at the same place, where the pattern origin is in the other sketch.

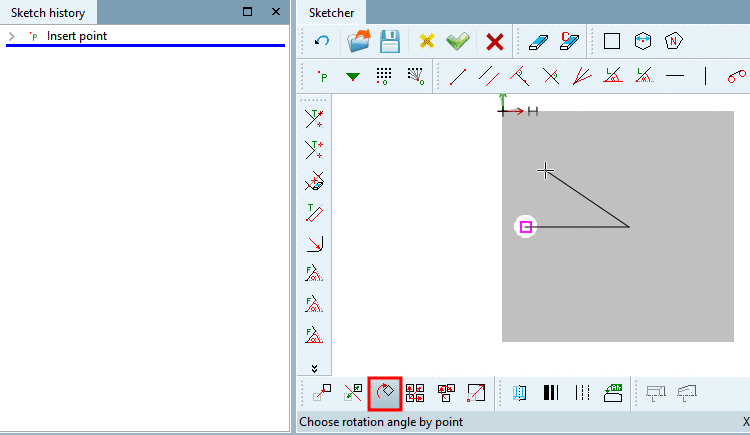

With pressed Ctrl key, click on the button Rotate selection

.

.

Follow the notes in status line:

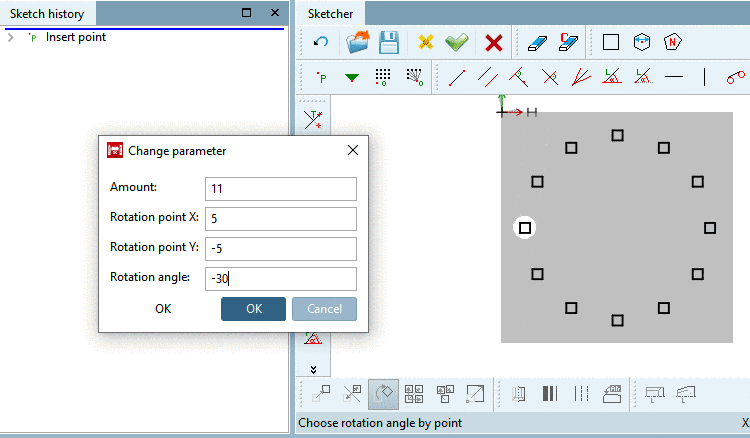

Adjust the values in input fields for Amount, Rotation point and Rotation angle and confirm with .

Delete the base point via Delete element

, because it would be created twice otherwise. The

base point is in another sketch.

, because it would be created twice otherwise. The

base point is in another sketch.In 3D History, mark the design steps Cut extrude and the sketch, which contains the pattern (here in example Sketch 3) and in the context menu, click Create pattern.

-> The borings are copied according to the pattern.

Align borings to reference point

![[Note]](https://webapi.partcommunity.com/service/help/latest/pages/jp/ecatalogsolutions/doc/images/note.png)